Alone there were 138 900 sheet metals workers recorded in the year.

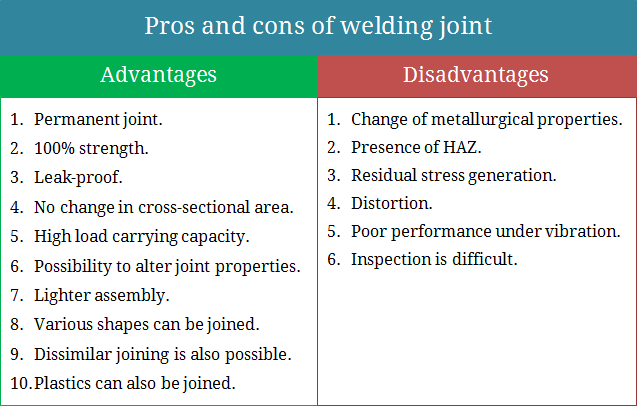

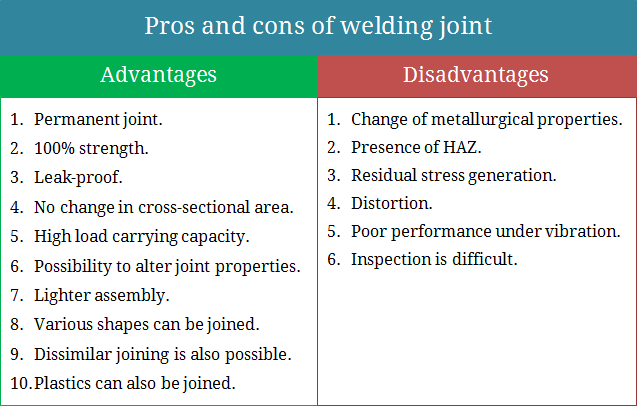

Advantages and disadvantages of sheet metal working.

Sheet metal can also be repaired relatively easily which makes it a practical choice in many different applications.

Pros of sheet metal roofing.

It produces good surface finish.

Metal can go through a wider range of processes including chipping.

This allows the process to work well with most softer metals such as aluminum brass bronze and mild low carbon steel.

Metal roofs come in a variety of materials and there is a lot of versatility on the market.

Because it takes less tooling time to laser cut or bend the metal it s advantageous cost wise.

More advantages of sheet metal fabrication lower production expenses on simple or complex designs if a metal that is used in sheet metal fabrication has the same width all around manufacturers save on the cost of production compared to cnc machining.

Sheet metal working process 2 17 2016 compiled edited by sivaraman velmurugan 33 disadvantages of hot working lower dimensional accuracy higher total energy required which is the sum of the thermal energy needed to heat the workpiece energy to deform the metal work surface oxidation scale thus poorer surface finish shorter tool life dies and rolls in bulk deformation.

Steel is the most.

And once you have this answer you will be ready to objectively assess the advantages of working in the sheet metal business.

Its relatively low cost is also an advantage in both one off design situations and in situations involving large quantities for mass production.

Even if the temperature rises a bit metal does not easily degrade.

Seven advantages of sheet metal fabrication.

Advantages of metal shearing process shearing performs straight line cuts without forming chips or burning or melting the material.

Sheet metal forming process advantages and disadvantages 1.

There are many benefits and a few of them are listed here for you to consider.

However the disadvantages are that forming times are long production rates are low and the parts are not suitable for high temperature use.

This process is also used for straightening parts.

Metals have higher melting points.

Metal is harder and stronger than plastic.

Peen forming is suitable for shallow contours on large sheets.

This process is for long parts with constant complex cross sections.

Bending is a manufacturing process that produces a v shape u shape or channel shape along a straight axis in ductile materials most commonly sheet metal.