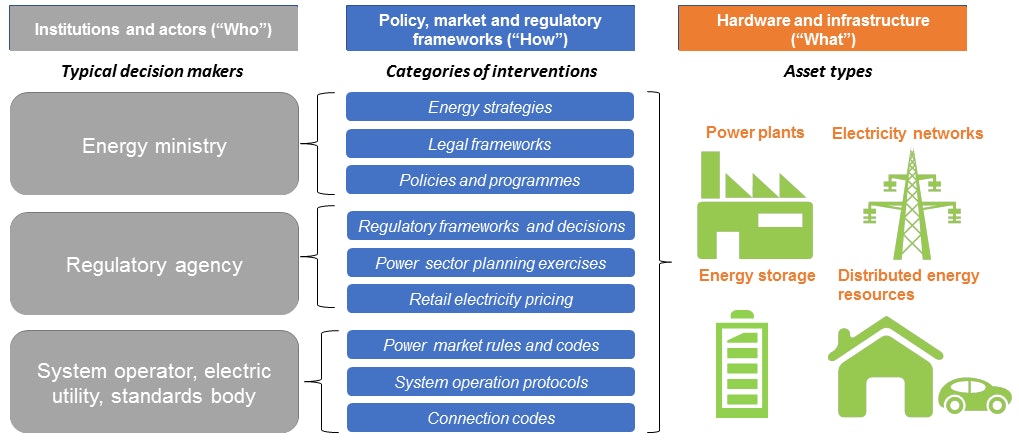

As individual devices in industrial settings become more connected and iot deployments accelerate power quality information from distributed equipment will be collected and leveraged in new ways.

Advanced power quality monitoring system.

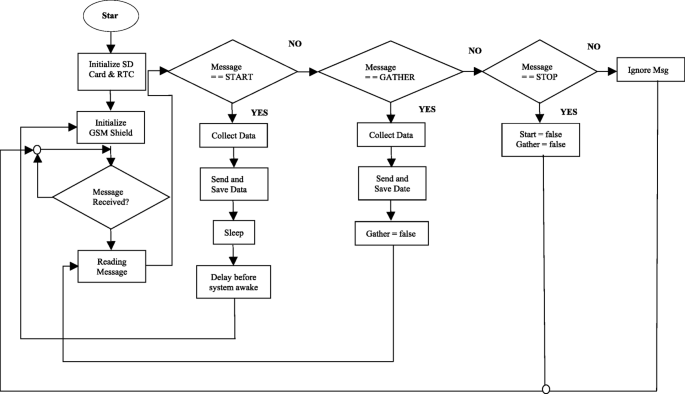

A power monitoring system provides an easy way to automatically retrieve and analyze power quality events.

The increased amount of data being collected requires more advanced analysis tools.

Opportunities for big data analytics that drive better energy intelligence.

Monitor equipment safely from anywhere.

Smart meters are capable of monitoring measuring and logging the components of an electric system including real apparent and reactive power as well as active energy consumption.

Power quality monitoring has advanced from strictly problem solving to ongoing monitoring of system performance.

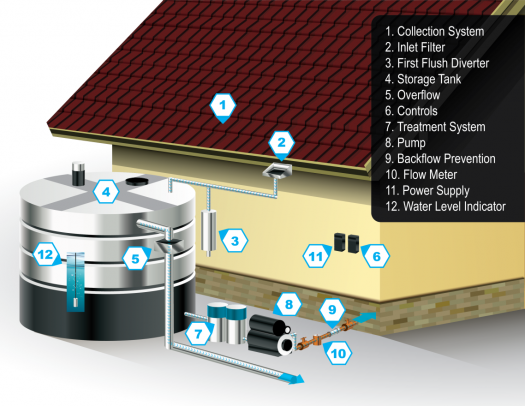

Some of the categories of equipment that can be incorporated into an overall monitoring system include the following.

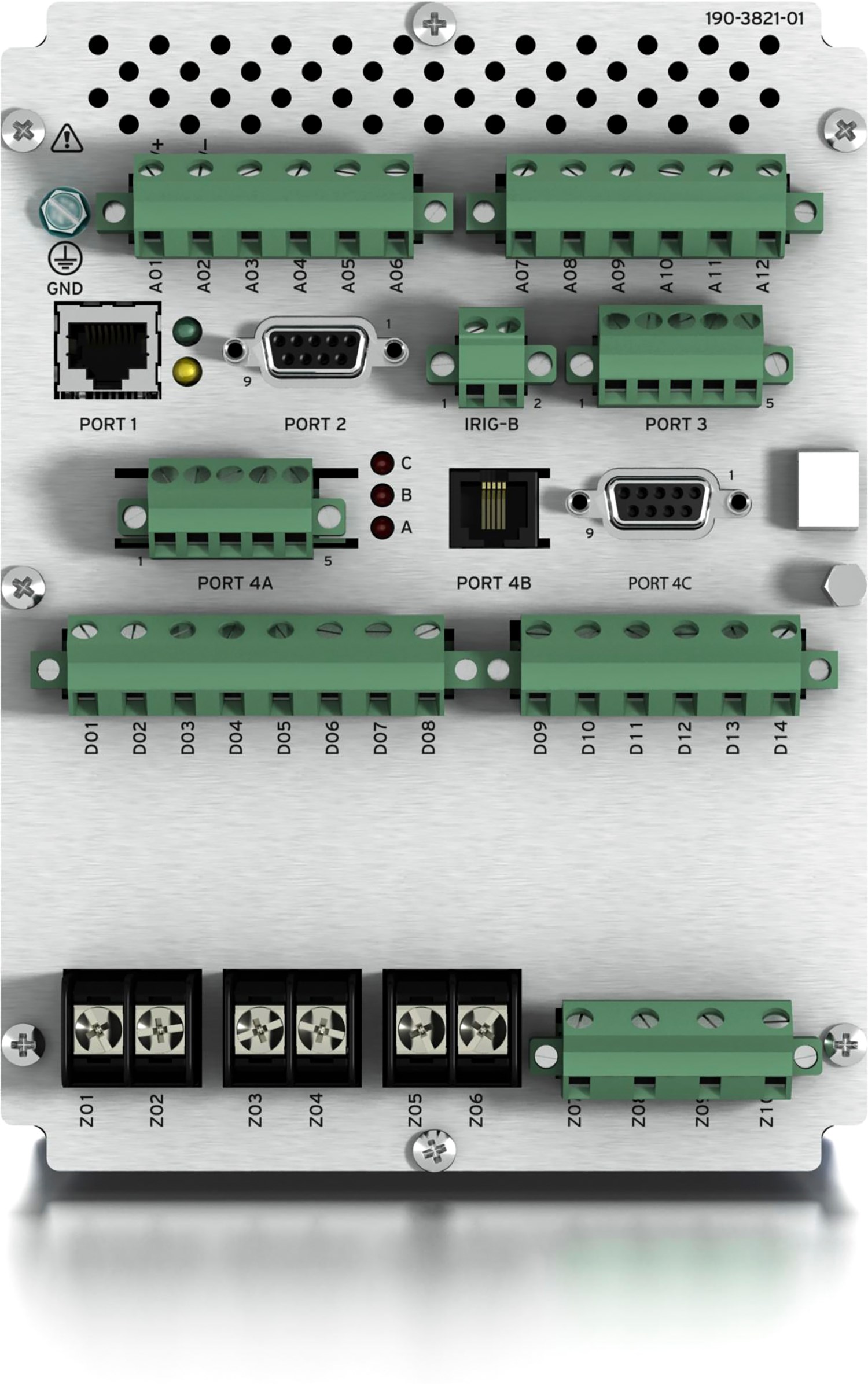

The epm 9900 is one of the most advanced monitoring products on the market today providing you with the total picture of energy usage and power quality from any metered point in a power distribution network.

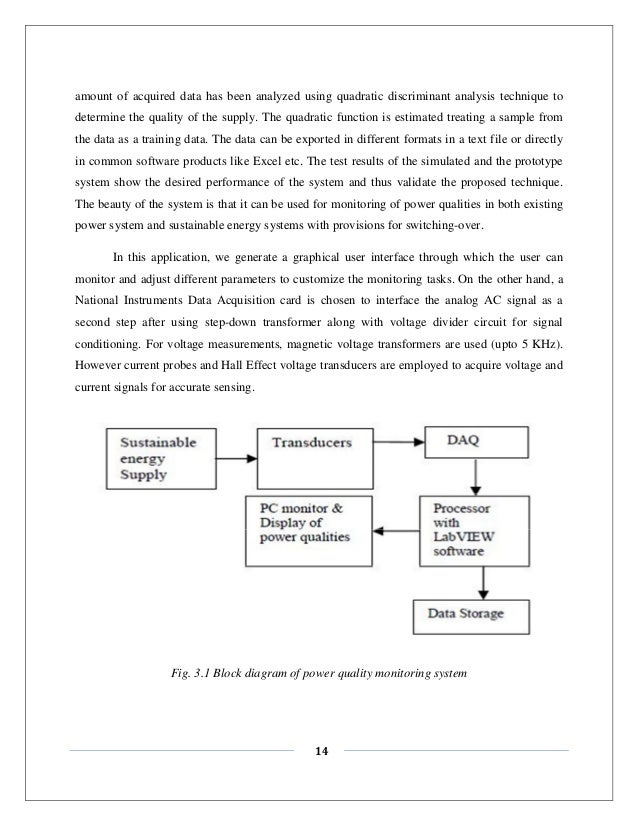

In short power quality monitoring system monitors the quality of voltage and current produced by a power plant.

Ensure that energy running to assets meets specification.

Total harmonic distortion thd is a key indicator of potential power problems.

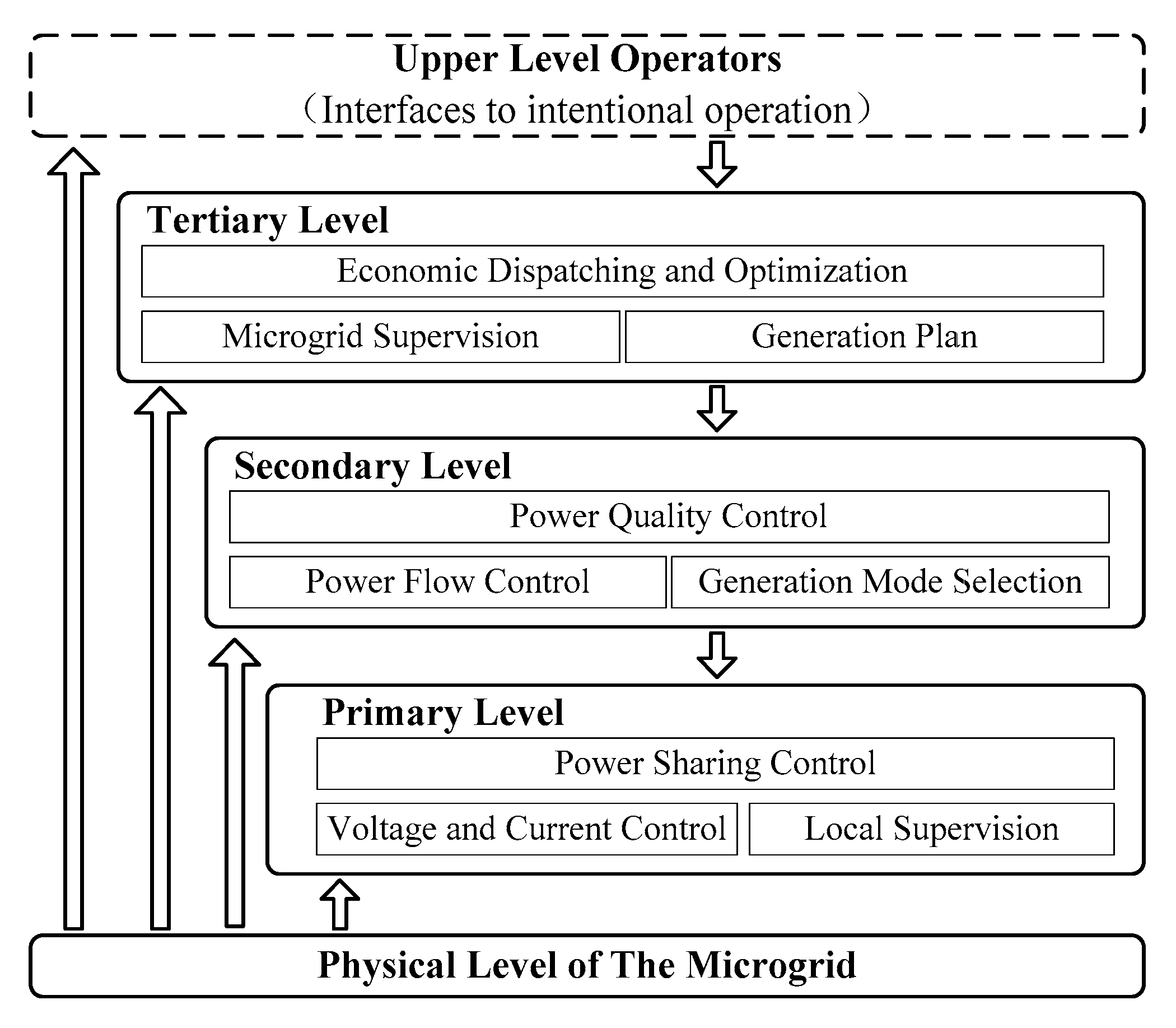

Permanent power quality monitoring systems such as the system illustrated in fig.

Typical power quality monitoring system signal chain.

Unlike building automation software which typically counts the number of events a power monitoring system extracts event forensics.

The sel 735 power quality and revenue meter is fully class a compliant to the iec 61000 4 30 power quality standard.

Types of power quality variations are described and the methods of.

This allows you to make power related decisions quickly and effectively.

A good system will also improve the performance efficiency and longevity of power generating equipment.

If you aren t going to invest the time money and resources needed to effect change and improve your customer experience you don t need a quality monitoring program.

Quality monitoring programs have the potential to make significant contributions to the success of a contact center but they must be done right.

5 1 should take advantage of the wide variety of equipment that may have the capability to record power quality information.

As you might imagine power quality monitoring is exactly what it sounds like measuring the power quality of your building.

:max_bytes(150000):strip_icc()/Airthings-f8db24f2c0a444fa8c9230772f325a55.jpg)